Guntur Spinning Mills Pvt Ltd (GSM) is a private limited company, with an experience of 18 years with an initial capacity of 15600 spindles to manufacture 100% cotton yarn. And later in 2015 Company expanded by an additional 17280 spindles. Currently the total capacity is 32880 spindles producing 15 tons of yarn per day.

In 2020 the Spinning division was upgraded to a 100% spindle monitor system by Premier Evolvics. GSM manufactures 3 varieties of yarn with count ranging from 30’s to 60’s ( combed compact , carded compact, hosiery compact ) selling in India and exporting to many Asian countries.

As a result, over the last few years, the company has been actively looking at Rooftop solar as a possible means to reduce its carbon footprint. This is where SafEarth came in and helped make their dream become a reality. The Rooftop CAPEX Solar installation of 1.3 MW has helped Guntur Spinning Mills Pvt Ltd reduce 2455 tonnes of CO2 emissions a year.

Project Details :

| Characterisitics | Value |

| Size | 1.3 MW |

| Commercial Operation Date (COD) | March 2024 |

| Type | Rooftop |

| Financing Mode | CAPEX |

| Execution Time | 5 Months |

| Annual Generation | 1, 753,700 kWh |

| CO2 Reduction | 2455 Tonnes |

| Levelized Cost of Energy | < INR 1.7 / kWh |

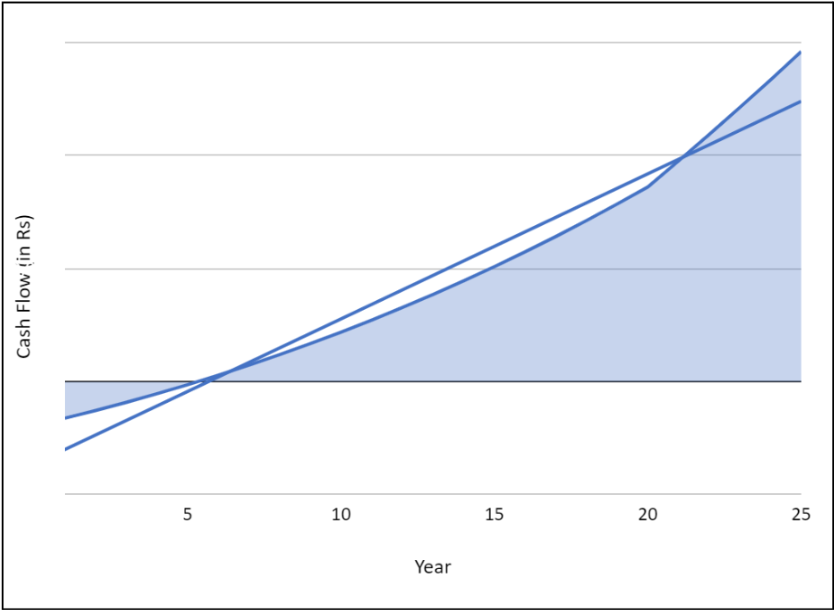

*Graph of Total Annual Cash Flow

The exact details are confidential. This is for visual representation only

The project closed with significant benefits to the off-taker and the company stands to save upwards of with the installation of the rooftop solar system by SafEarth.

Project Workflow

SafEarth is proud to be a part of this journey. This is how we helped their transformation:

Project Design:

Upon signing with Guntur Spinning Mills Pvt Ltd, SafEarth first visited the site and made a detailed engineering report for the project. The designed system optimized the generation and the return on investment of the plant. Best industry practices have been used in this system.

Vendor Selection:

The SafEarth team then selected vendors from the companies registered on our portal. All these companies are industry leaders.

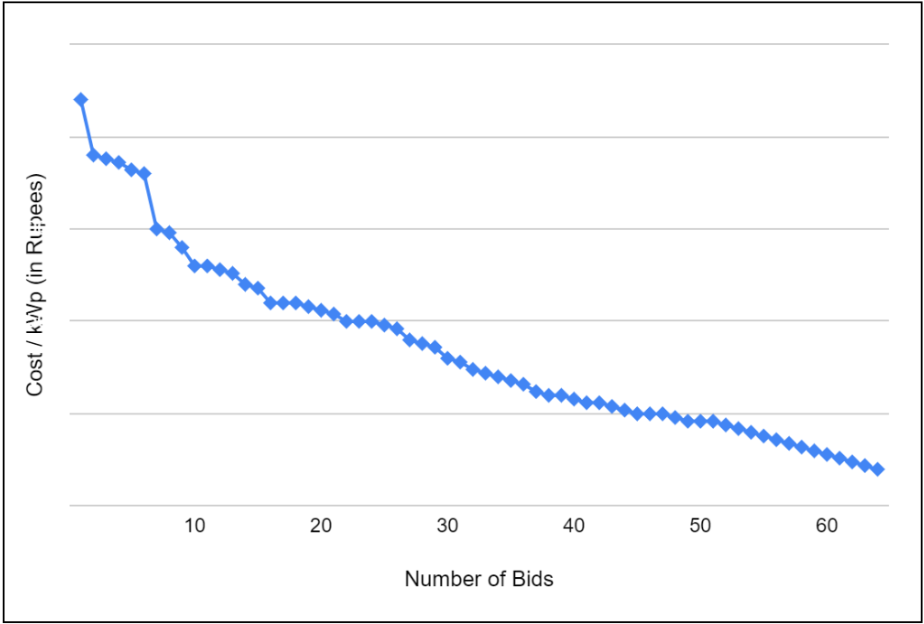

Online Auction:

These companies were given a week to review the Detailed Engineering to help them ascertain their costs up to 99% accuracy. They then participated in an Online Reverse Auction on our Platform.

*Graph of Auction Analysis

The exact details are confidential. This is for visual representation only

Negotiations:

After the auction, Guntur Spinning Mills Pvt Ltd selected a vendor from the participating vendors and held final discussions with this vendor. We worked with them to iron out various terms and conditions of the contract to arrive at a Win-Win scenario. This ensured protections for the client as well as the vendor.

Installation:

After the closure of the financing negotiations, the Vendor installed the plant on the roof of the industry following the best in industry practices. The plant has been set up using premium components and has been designed for top-grade performance.

Quality Assurance by SafEarth:

Before Commissioning and Handing over the plant, the SafEarth quality team visited the site and identified any punch points related to the project. The plant was handed over only after resolving these punch points.

Operations and Maintenance:

The O&M for the plant is now being done by the Vendor. The contract sets out clear benchmarks against which the output of the plant will be evaluated.

Auction Summary :

| Number of Bidders | 15 |

| Total Number of Bids | 64 |

| No. of Bidders Matching | 1 |

| Average Savings | ~ ₹ 14,000,000 |

| Closure Time – Post Auction | 15 Working Days |

Final Outcome of Project

SafEarth has helped Guntur Spinning Mills Pvt Ltd reduce its carbon footprint by 2455 tonnes per year of CO2 equivalent and save over 60% of their electricity bills in the process. The Company was able to get the best quality solar plant without having to worry about any aspect of the project and as a result, they have awarded additional projects to SafEarth.

Ready to buy a solar system? Join us on our SafEarth Platform to get the best quality and prices for your system !