Allied Founders Pvt Ltd founded in 1968, is a well-established company based in Belgaum, Karnataka, India, that has been in business for 55 years. Specializing in manufacturing and exporting Grey Iron and Ductile Iron Castings, Machined Components & Assemblies, the company produces a wide range of products.

The company ensures that it has a quality management system in place that meets international standards. With a CNC machine shop that supplies nearly 100% of its castings in fully machined condition to Original Equipment Manufacturers (OEMs), the company has an installed capacity of 4200 Metric tons per annum with 25% spare capacity as of March 2023.

As a result, over the last few years, the company has been actively looking at Rooftop solar as a possible means to reduce its carbon footprint. This is where SafEarth came in and helped make their dream become a reality. The Rooftop CAPEX Solar installation of 125 kW has helped Allied Foundries Pvt Ltd reduce 258 tonnes of CO2 emissions a year.

Project Details :

| Characteristics | Value |

| Size | 125 kW |

| Commercial Operation Date (COD) | December 2020 |

| Type | Rooftop |

| Financing Mode | CAPEX |

| Execution Time | 4 Months |

| Annual Generation | 184,375 kWh |

| CO2 Re4duction | 258 Tonnes |

| Levelized Cost of Energy | > INR 1.5 / kWh |

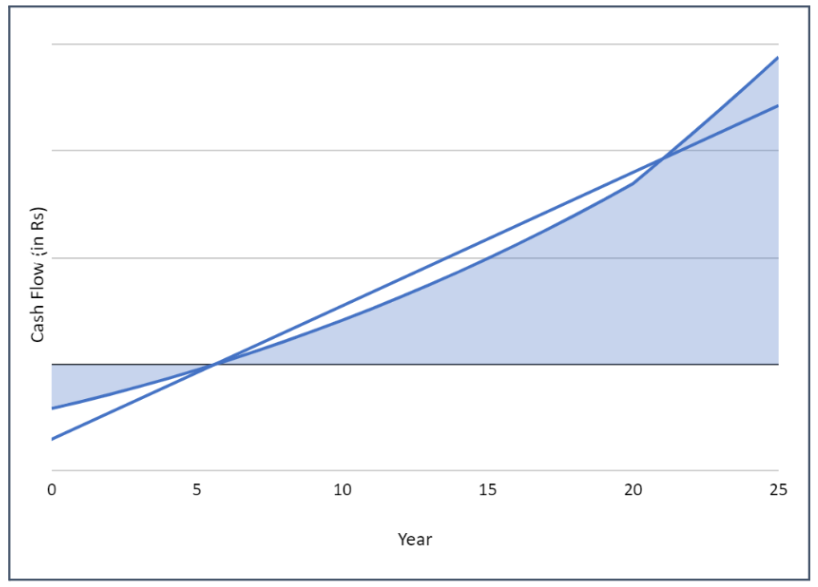

*Graph of Total Annual Cash Flow

The exact details are confidential. This is for visual representation only

The project closed with significant benefits to the off-taker and the company stands to save upwards of with the installation of the rooftop solar system by SafEarth.

Project Workflow

SafEarth is proud to be a part of this journey. This is how we helped their transformation:

Project Design:

Upon signing with Allied Foundries Pvt Ltd, SafEarth first visited the site and made a detailed project report for the project. The designed system optimized the generation and the return on investment of the plant. Best industry practices have been used in this system.

Vendor Selection:

The SafEarth team then selected 15 pre screened vendors from the companies registered on our portal. All these companies are industry leaders. These companies were given a week to review the Detailed Project Report to help them ascertain their costs up to 99% accuracy. After that they selected a vendor from the 15 participating pre screened vendors and held final discussions with this vendor. We worked with them to iron out various terms and conditions of the contract to arrive at a Win-Win scenario. This ensured protections for the client as well as the vendor.

Installation:

After the closure of the financing negotiations, the Vendor installed the plant on the roof of the industry following the best in industry practices. The plant has been set up using premium components and has been designed for top-grade performance.

Quality Assurance by SafEarth:

Before Commissioning and Handing over the plant, the project goes through multiple quality checks i.e., at the initial phase of the project, during installation and before commissioning. The SafEarth quality team visited the site and identified any punch points. The plant was handed over only after resolving these punch points.

Operations and Maintenance:

The O&M for the plant is now being done by the Vendor. The contract sets out clear benchmarks against which the output of the plant will be evaluated.

Final Outcome of Project

SafEarth has helped Allied Foundries Pvt Ltd reduce its carbon footprint by 258 tonnes per year of CO2 equivalent and save over 30% of their electricity bills in the process. The Company was able to get the best quality solar plant without having to worry about any aspect of the project and as a result, they have awarded additional projects to SafEarth.

Ready to buy a solar system? Join us on our SafEarth Platform to get the best quality and prices for your system !